Wood leg vise screw Backyard arbor

Step 1: Plan / Design I played with the plan in AutoCAD for a few days. At first I didn't have the slide (I don't know what it should be called, see the picture below to see what I'm talking about). The purpose for the slide is to keep the jaws parallel so that the whole face of the jaw holds the work piece, not just the top or bottom).

Benchcrafted to Introduce Nopin Leg Vice

Step 5: Place the Leading Screw. Drill a hole that will go through the vise and the table leg, big enough to let the leading screw pass through. When you do so, keep the vise in place and the supporting leg in the slot of the table leg. Make sure the Vise is perfectly vertical when you drill the hole. Attach the leading screw and the screw base.

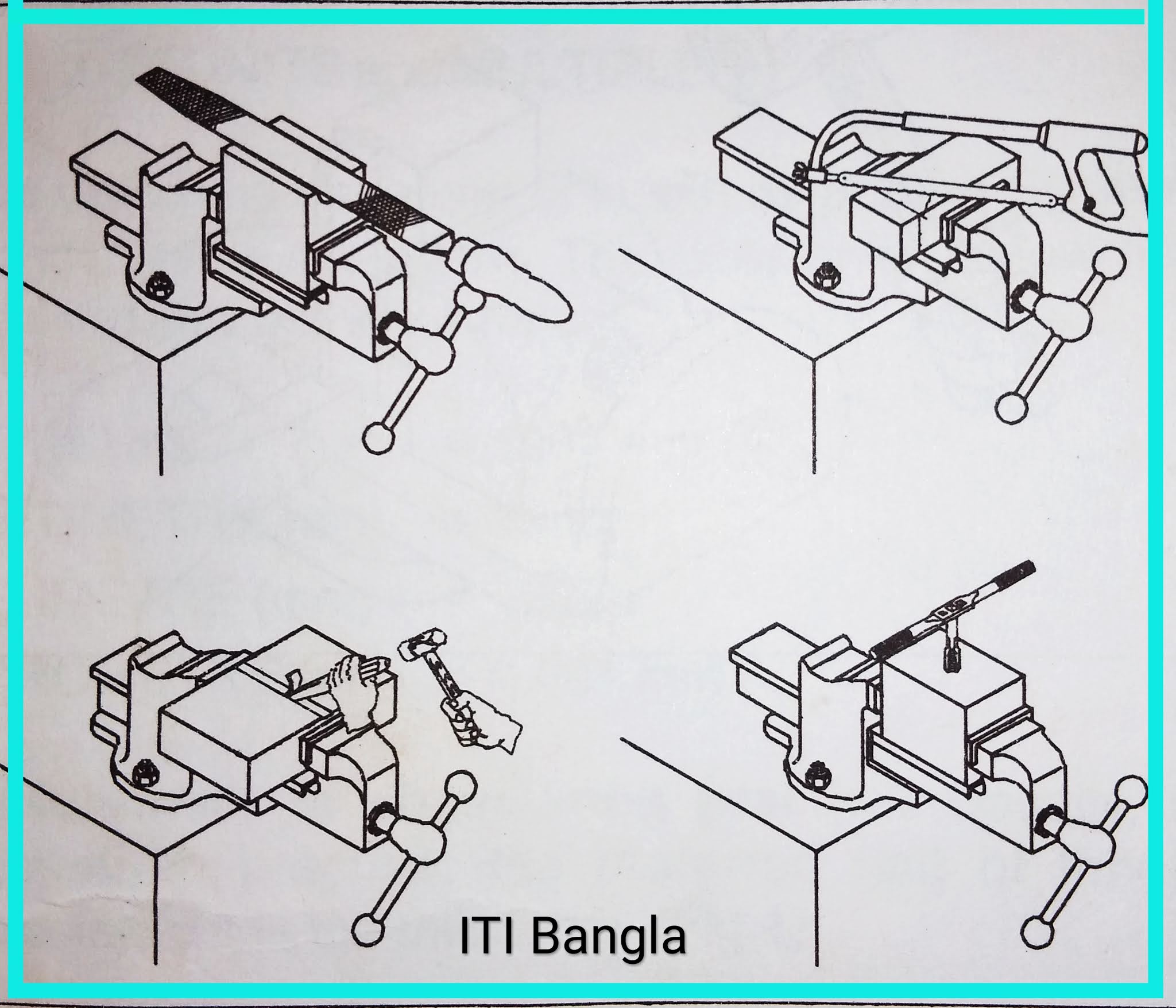

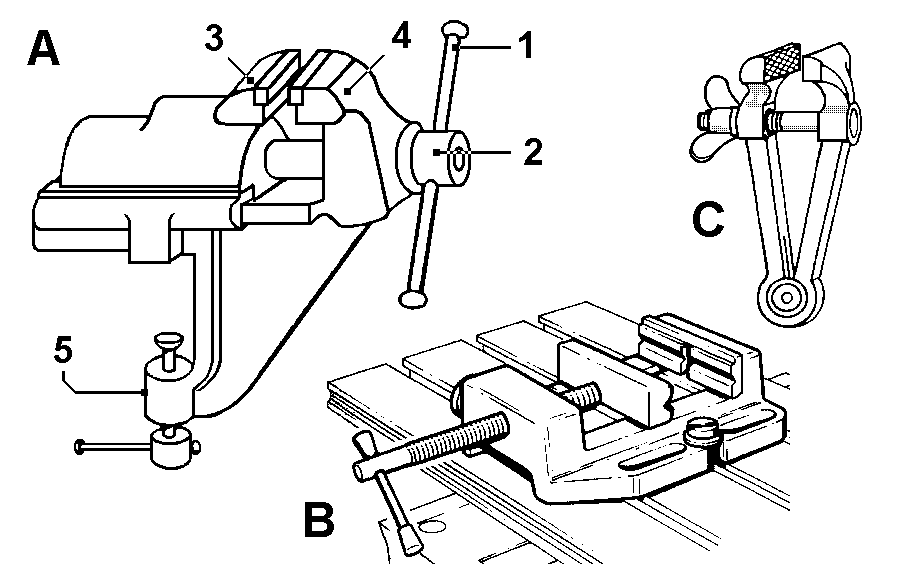

Types of Vices, Bench Vice, Machine Vice, Pipe Vice, Hand Vice, Leg Vice, Pin Vice,Tool Maker Vice.

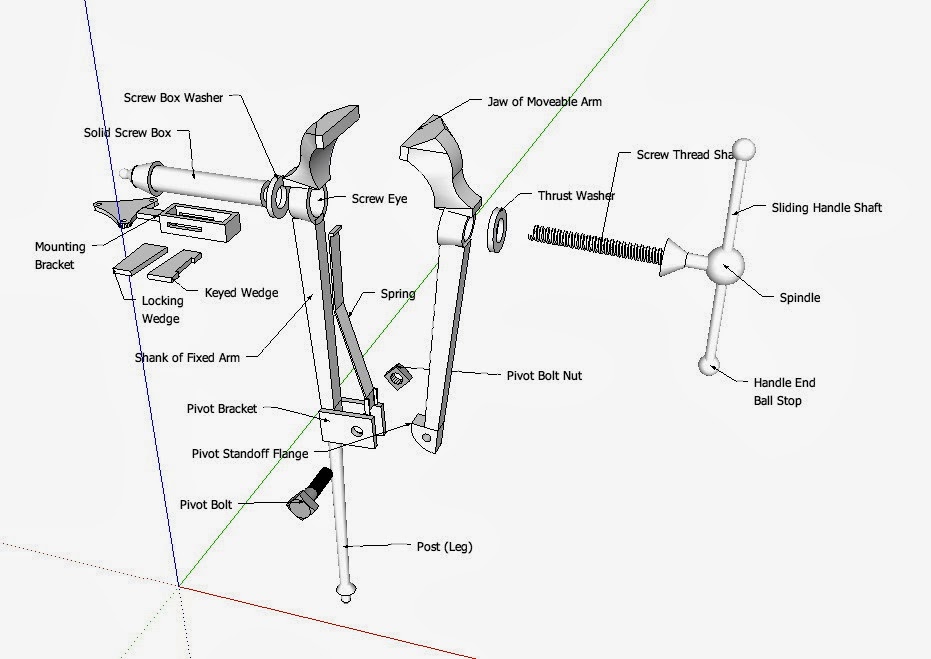

Basic Leg Vise Types Before making replacement parts for a vise, it is important to determine what the missing ones looked like. In keeping with our restoration approach, we made parts of the correct style, not simply ones that worked.

How to build a workbench vise Diy work bench

Ask Question Download Step 3: Mounting the Vise Screw Collar For this leg vise, I decided to go with a Yost 18" Vise Screw. It's plenty strong, relatively cheap, and turns easily. I mounted the vise-screw's collar to the rear of the leg using four 3" #14 screws.

How to make a leg vise for the workbench. DIY leg vice YouTube

The leg vise is perhaps the most unusual feature of this circa 1768 workbench. As shown in Plate 11, the vise has neither a parallel guide, nor a garter. Also unusual: the vise's jaw is quite close to the floor. When I built this vise, I had misgivings about missing these features - the parallel guide and garter - I am so fond of.

Persimmon Professional Blacksmithing Post Vise Diagram

To use it, simple grab the piece you're wanting to hold in the vise. Close the vise until it makes a little bit of contact at the top. Then, use your foot to kick in the wedge until it engages with the vise at the bottom. Then, turn the handle of the vise about another 1/8 turn and it will be very solid.

Traditional Workbench Bench Screws [Vise] Woodworking vise, Woodworking apron, Woodworking

VX21 Face Vise Instructions. The Hovarter Custom VX21 face vise is a revolutionary new quick action vise mechanism based off of the popular VX21 leg vise. The VX21 face vise utilizes a special clutch mechanism to allow the vise jaw to be quickly positioned against the workpiece. The two separate vise mechanisms operate in unison by a unique.

A Guide to Vises

The Leg Vice - Simple & Heavy Duty by Richard Maguire | Aug 24, 2012 | 9 comments Leg Vice (De-)Evolution I've spent a lot of time lately developing Crosses and Shafts for a pin less leg vice. So it's been easy for me to loose sight of just how good the simple original really is.

Leg Vice

Next, it is placed near the end of the leg. I use a marking knife to mark out where it will go then cut out a mortise to fit the bar. This only goes half the way through the chop. Next, those marks are transferred to the bench leg and a through mortise needs to go through the leg for the spreader bar to go through.

KIEFER LEG VISE DIAGRAM SKETCH by kiefer woodworking community

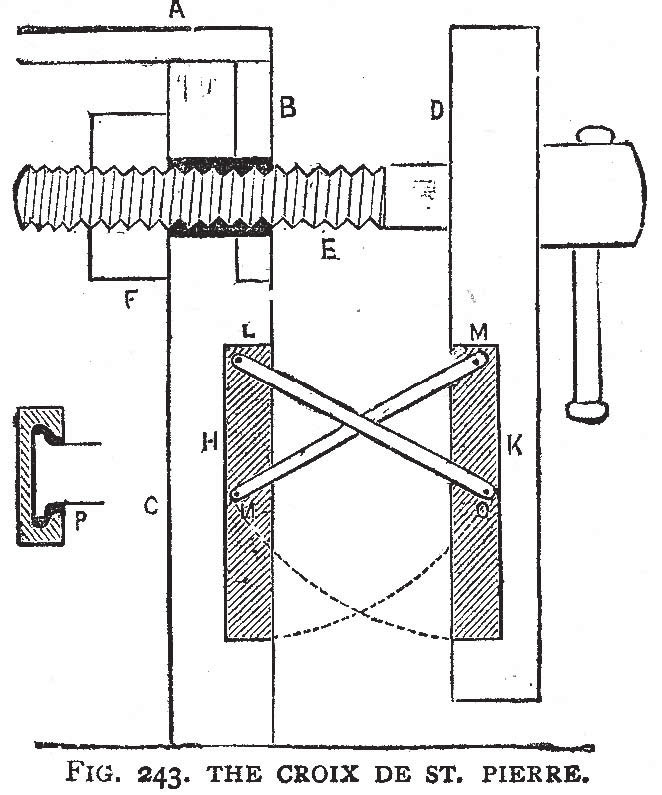

Step 1: St. Andrew's Cross On many traditional workbenches the chop is held parallel with a sliding wooden guide which is shot full of holes. The worker must place a pin in the hole closest to the bench when the vise bottoms-out. This procedure can get tiresome after a while.

LEG / POST VISE (now van be called blacksmith Vise) Dimensions/ weight Blacksmithing, Vise

A leg vise moves via a single screw with a pinned sliding guide rail to maintain parallelism. The guide-rail pin rests against end-grain hard-maple pads that prevent compressing the softer alder leg of this bench. * The pin and sliding guide rail keep the jaw parallel for even clamping force. Reposition the pin for the workpiece you're clamping.

Pin on Good to know

How to Make a Wood Vice As is the case with most projects in the shop, learning how to build a woodworking bench vise can be as easy or challenging as you want to make it. I would break down this project into: Modifying a metal vice; Repairing a used vice; Buying and building a kit; Building a vise from plans. Modification

HOW TO DRAW A VISE YouTube

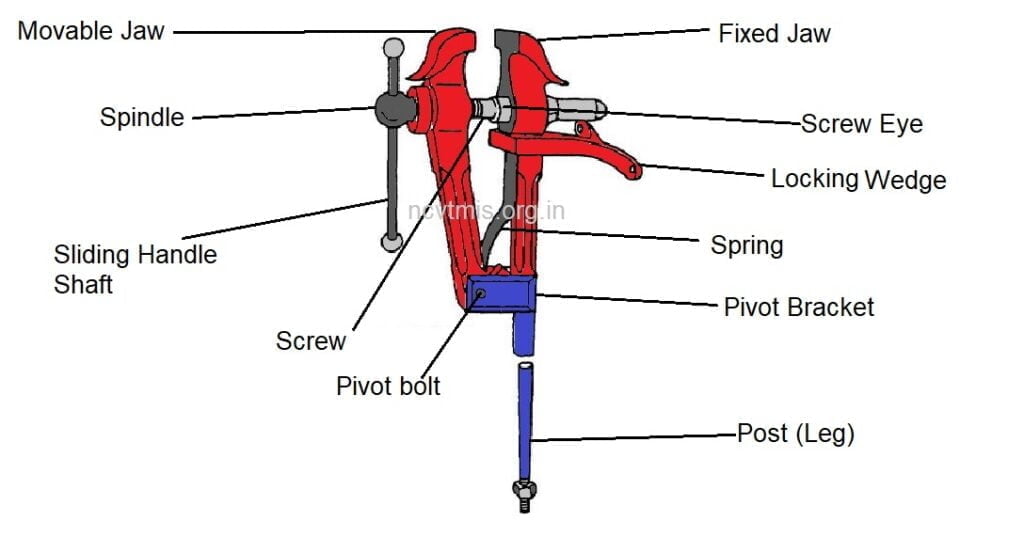

Leg Vice Carpenter Vice Hand Vice Combination Hand Vice Pin Vice Tool Makers Vice Drill Vice #1 Bench Vice: The complete construction of this vice is made of cast iron. Both its jaws are made of tool steel. The spindle handle is made of mild steel.

Leg Vice Blacksmith and Vocational Studies Tilgear

Leg vises typically use the left front leg of the bench as the rear jaw of the vise. The screw of the vise was either threaded into the leg or a separate wooden vise nut was attached to the bench leg. In some instances the leg vise is mounted on sliding rails on the bench face to allow it to be moved to the most advantageous location.

DIY Garden Bench Ideas Free Plans for Outdoor Benches Diagram Line Diagram Bench Vice

SHAPING THE LEG VISE: Next up was shaping the leg vise a bit. To do this, I chose a spot a little above halfway up and then a place about 2 or so inches in from either side at the bottom, struck a line and cut that out on the bandsaw. Then, I took the entire leg vise over to my miter saw and cut the top front face of it about 2/3 of the way.

वाइस (Vice) किसे कहते है कार्य प्रकार एवं सावधानियाँ NCVT MIS

A technique that is less commonly seen than the parallel guide is featured in the workbench below and uses a simple wooden rod that bears within a hole through the bench leg.